PureCell® technology offers a wide range of benefits, from improving the environment and keeping us less dependent on the grid, to space- and cost-saving attributes and more.

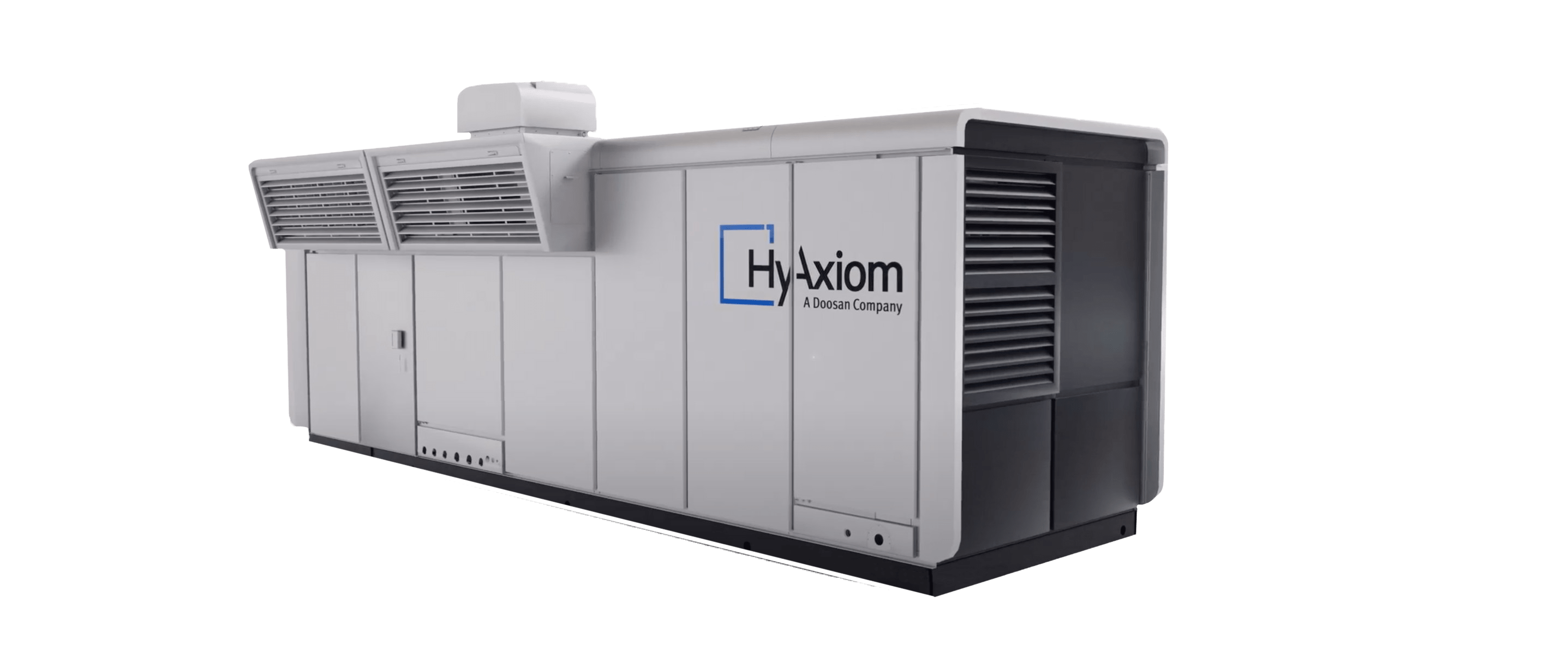

HyAxiom develops innovative energy solutions to power your business. Our fuel cell technology is a clean, reliable and cost-effective way to generate continuous energy for buildings and microgrids.

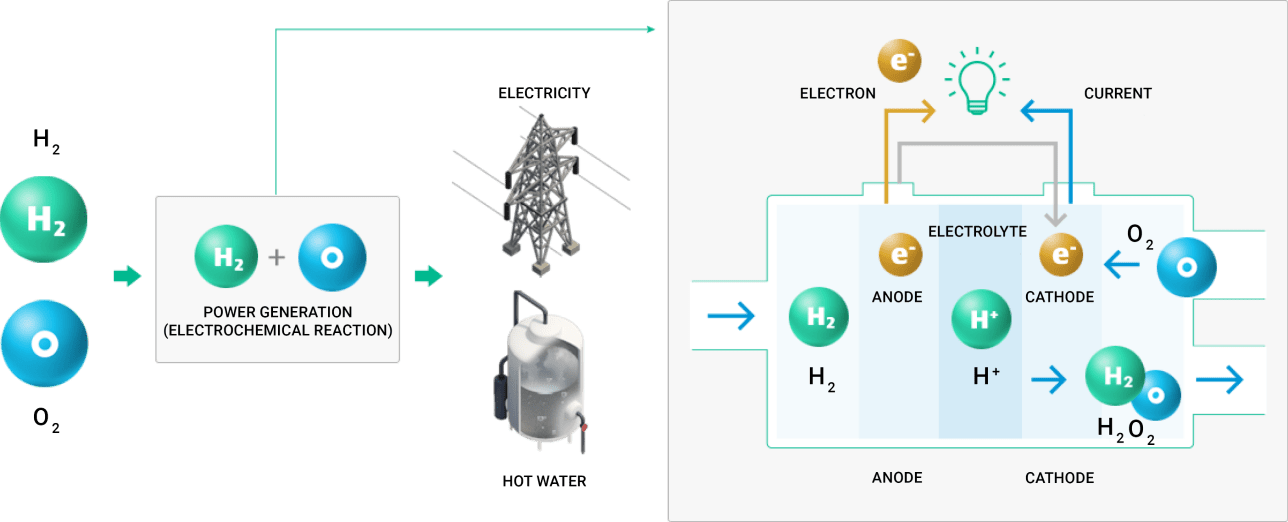

How Fuel Cells Work

About PureCell®

Our current core product offering is based on a phosphoric acid fuel cell (or PAFC) that has stationary applications, meaning fixed at a location to generate electricity, as opposed to mobility and transport applications. We are actively developing a portfolio of new products based on next-generation technologies—for both stationary and mobile applications—to capture new growth opportunities across the hydrogen value chain. Our products in development are designed to deliver a full spectrum of reliable, cost-effective hydrogen solutions for stationary and mobility/transport (both land and sea) transportation, as well as green hydrogen production.

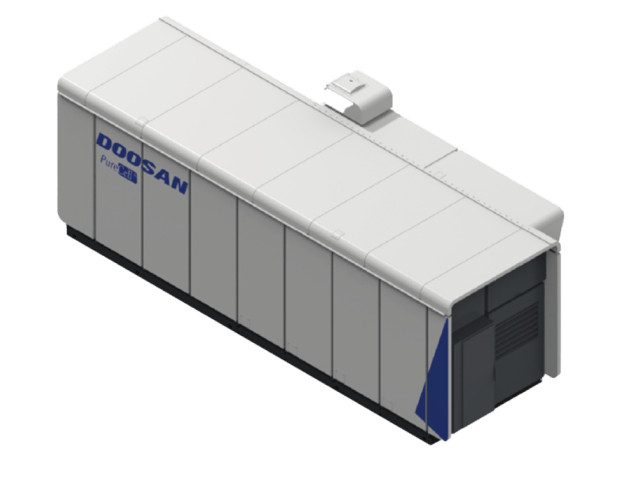

Our PureCell® product is a 440-kilowatt stationary, modular unit that generates electricity and heat from hydrogen, natural gas or liquefied petroleum gas (LPG), with each unit capable of powering over 340 average U.S. households. It operates quietly, has a small footprint for flexible installation and has low or no greenhouse gas emissions because it uses an electrochemical process rather than combustion.

In addition, our PureCell® units have an expected system life of 20 years and an expected cell stack life of 10 years, which are among the longest in the fuel cell industry today. Our PureCell® product has a competitive advantage in efficiency, durability and pricing in combined heat and power (CHP) applications.

Our customers rely on us for technical maintenance and support services because we are the most dominant and the largest manufacturer of PAFC technology with the capability to effectively monitor and service our products.

Clean.

Reduce your carbon footprint with PureCell®. Our units enrich and revitalize communities by reducing greenhouse gasses, lowering air emissions and saving water—all with scarcely more noise than keystrokes on a piano.

Independent and Resilient.

PureCell® units can provide electricity and heat completely independent from the utility grid, keeping critical operations running in the face of power outages resulting from man-made and natural disasters.

Compact.

PureCell® units are approximately the size of a standard commercial shipping container. This compactness allows them to be installed with a minimal footprint, including in a stacked formation.

Cost Effective.

Thanks to its industry-leading energy efficiency, especially in combined heat and power applications, PureCell® units help you to reduce your energy costs.

Our Products

PureCell® Model 400 NG

Efficiency

Electricity

Heat

PureCell® Model 400 NG

Key Features & Benefits

PureCell® Model 400 Hydrogen

Efficiency

Electricity

Heat

PureCell® Model 400 Hydrogen

Key Features & Benefits

PureCell® Model 400 LPG/NG Dual

Efficiency

Electricity

Heat

PureCell® Model 400 LPG/NG Dual

Key Features & Benefits

Upcoming Hydrogen Solutions

HyAxiom is at the forefront of the hydrogen revolution, delivering a full spectrum of reliable, cost-effective hydrogen solutions. From scalable, green, on-site hydrogen production and long-haul maritime solutions to comprehensive, end-to-end solutions for the commercial vehicle mobility market, our products in development are all designed to help power your carbon-free future. Our current product line-up consists of electrolyzers (i.e., for green hydrogen production) and a diversified set of hydrogen fuel cells for stationary as well as land- and sea-based mobility and transport applications.

Proton Exchange Membrane Electrolysis Cell (PEMEC)

PEM electrolyzers (PEMEC) generate hydrogen by breaking up water molecules. When powered by renewable sources of energy, such as solar or wind, the clean hydrogen produced can be used for on-site application such as blending with natural gas as feedstock for combined cycle power plants or to be stored and transported to other demand sources, thereby acting as an alternative storage mechanism to battery storage systems for renewable energy. PEMEC has load-following capability—the ability to adjust output as electricity fluctuates throughout a day—making it suitable for utilizing electricity generated by wind and solar. Since many governments provide significant subsidies to clean hydrogen users, PEMEC is expected to experience substantial growth in countries with substantial wind and solar assets, such as Europe, Australia and the United States.

To capture the large commercial opportunity in on-site clean hydrogen production, we are developing a 1-megawatt PEMEC as part of a South Korean government-funded R&D initiative. The first unit is expected to be installed for testing and demonstration in South Korea in 2023; the second unit in the United Arab Emirates in 2024.

Solid Oxide Fuel Cell (SOFC)

Solid oxide can achieve greater efficiencies due to faster kinetics at higher operating temperatures. Leveraging the know-how from our PAFC technology, we are developing a 300-kilowatt solid oxide fuel cell (SOFC) product in conjunction with a strategic partner. The SOFC product is designed to have higher electrical efficiency compared to our PAFC products, and greater reliability and cost efficiency compared to other SOFC products currently in the market. Additionally, by using nearly identical reversible solid oxide stack design for our solid oxide fuel cell and electrolyzer, we are seeking to drive efficiencies and manufacture solid oxide products at scale. This SOFC product will augment our product portfolio for the stationary fuel cell market, particularly for around-the-clock mission-critical applications such as data centers and ships.

Solid Oxide Electrolysis Cell (SOEC)

Solid oxide electrolyzers have higher efficiency for volume production of hydrogen than other electrolyzers. However, to ensure high efficiency, the SOEC requires heat. The SOEC produces approximately three to four times more hydrogen at the same power level as PEM electrolyzers when excess heat is available. It also has a higher maximum operating current limit, which allows for better utilization of higher amounts of curtailed energy. As such, SOEC is competitive in sites that produce high-grade heat and cheap electricity, such as nuclear power plants. However, since a SOEC operates in a high heat environment (560 to 800 Celsius), load-following is difficult and therefore not particularly useful for connectivity with solar and wind energy sources. As SOEC technology matures in terms of durability and achieves lower product cost, we expect this technology to capture a majority of the clean hydrogen generation market.

Leveraging our expertise and experience from developing our solid oxide fuel cell product, we plan to initially develop a 1-megawatt solid oxide electrolyzer system prototype, with plans to add this prototype to a multi-megawatt system for clean hydrogen production. We will target industrial, utility and independent power producer customers who need to produce clean hydrogen at scale more efficiently than other electrolysis technologies.

Additionally, we plan to explore integrating our solid oxide electrolyzer system with the heat generated by a nuclear power plant, with plans to commence the pilot phase in 2027. We will target large-scale, energy-intensive, “hard-to-abate” industrial customers like steel, chemical and cement companies, and intend to produce onsite clean hydrogen more efficiently than lower-temperature PEM or alkaline electrolyzers.

Proton Exchange Membrane (PEM) Fuel Cell Powerpacks

For land-based transportation applications, we are developing a 100-kilowatt power pack, which is a fuel cell based on polymer electrolyte membrane (PEM) technology. These power packs are designed for large vehicles such as passenger buses, heavy- and medium-duty trucks and other industrial vehicles that use diesel engines, which, according to recent estimates, are responsible for 35% of global greenhouse gas emissions in the transportation sector in 2020.

In May 2022, we formed a wholly-owned subsidiary, HyAxiom Motors, to act as a bus fleet operator in South Korea to commercialize passenger buses fueled by our clean PEM fuel cell technology as a viable alternative to buses powered by traditional internal combustion engines. In addition, we are continuing to develop our PEM power packs for use in other applications such as heavy- and medium-duty trucks and other specialty industrial and commercial vehicles. We intend to design our PEM power packs to be compatible with our Tri-Gen System and PEM electrolyzers, with a target of offering a comprehensive solution for the commercial and industrial transportation sector.

Solid-Oxide Propulsion System

Building on our stationary SOFC technology and expertise, we are engineering a solid oxide fuel cell propulsion system for maritime use. The SOFC propulsion system is expected to be a viable solution for long-haul maritime vessels that will face new emissions requirements pursuant to the next phases of the Energy Efficiency Design Index (EEDI) issued by International Maritime Organization, a special agency of the United Nations responsible for the safety, security and sustainability of international maritime matters.

While certain improvements to the current LNG engines may provide a short-term solution to satisfy the next phase of requirements beginning in 2025, the industry will need a new technology to meet the demands of the subsequent phase, scheduled to come into effect in 2030. Given that the average life of a long-haul maritime ship is approximately 10 years, key shipbuilding and transport companies are actively seeking LNG engine alternatives that will secure longer-term efficiency to ensure they meet necessary regulations moving forward.

Our system is designed to be more efficient, durable and cost-effective than alternatives currently available in the market. In addition, our key focus is ensuring that our new technology has a greater life expectancy to align with the useful life of the ship it will power, given that the average life of a long-haul maritime ship is approximately 10 years.

Tri-Gen System

The Tri-Gen System, a modification of the PureCell® M400, co-generates on-site hydrogen, electricity and heat simultaneously, making it optimal for use in electric and hybrid vehicle charging stations. With this system, HyAxiom will provide a comprehensive, end-to-end solution for the commercial vehicle mobility market.

HyAxiom expects to install the Tri-Gen System units for a customer in South Korea in 2023, and we expect this system to be commercially available in the United States by the first quarter of 2023. Our products are intentionally designed to complement and be compatible with one another. Specifically, the hydrogen fuel cells we are developing for the transportation sector, as described above, will be designed to benefit from our Tri-Gen System’s ability to serve as hydrogen charging stations.