HyAxiom develops innovative energy solutions to power your business. Find out how.

Our Products

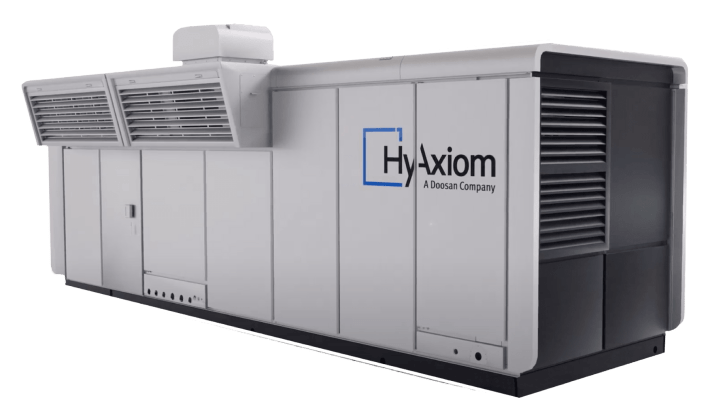

What is the PureCell® Model 400?

The PureCell® Model 400 uses proprietary phosphoric acid fuel cell (PAFC) technology and natural gas, hydrogen, LPG or a blend of fuels to generate electricity and heat through an electro-chemical process without combustion to power commercial, industrial and utility applications.

Clean

- Low/Zero emission electricity

- CARB DG certified

- Massachusetts 310 CMR7.03 compliant

- Zero water consumption below 86 °F ambient on NG; creates water on H₂

Reliable

- 95%-98% availability

- Protect critical assets during grid disturbances

- 60+ years of innovation

- Dedicated system service by HyAxiom personnel

Cost-Effective

- 10-year cell stack life

- Low maintenance requirements

- Equipment sale, lease or power purchase agreement

- Federal ITC eligible

Output & Efficiency

- 440 kW – 460 kW baseload electric

- 1.7 MMBtu/hr (250 °F) heat available

- 43% - 51% efficient electrical

- 90% Combined Heat & Power efficiency

Applications & Capabilities

- Combined Heat & Power

- Off-grid or grid-connected

- Load-following (10kW/s, 20kW/s)

- N+1 redundancy configuration

Additional Features

- Fuel flexible (H₂/NG/Blend)

- Modular and scalable

- Versatile siting options (indoor/outdoor/rooftop)

PureCell® Model 400

Hydrogen

90%

Efficiency

50%

Electricity

40%

Heat

PureCell® Model 400

Hydrogen

The stationary fuel cell uses the chemical energy of hydrogen to cleanly and efficiently produce electricity and heat without combustion. There are no air pollutants that create smog and cause health problems at the point of operation. The world’s first and largest hydrogen-fueled stationary fuel cell power plant (50 MW), which entered commercial service in 2020 in South Korea, is powered by the PureCell® M400

Key Features & Benefits

- Load Following

- Zero Emissions (No CO2, NOx , SO , or VOCs )

- 24/7 Power and Heat

- No water input required for operation in any rated ambient conditions

PureCell® Model 400

Natural Gas

90%

Efficiency

50%

Electricity

40%

Heat

PureCell® Model 400

Natural Gas

Using natural gas as fuel, this model can generate up to 460 or 440 kW.

Key Features & Benefits

- Load Following

- Zero Emissions (No SOx and NOx)

- 24/7 Power and Heat

PureCell® Model 400

LPG/NP Dual

90%

Efficiency

50%

Electricity

40%

Heat

PureCell® Model 400

LPG/NP Dual

Engineered to operate in areas without access to natural gas pipelines, this model can operate in dual modes and can serve as an emergency power supply.

Key Features & Benefits

- Load Following

- Zero Emissions (No SOx and NOx)

- 24/7 Power and Heat

- Fuel Flexibility Between LPG and NG

PureCell® Model 400

Tri-Gen System

90%

Efficiency

50%

Electricity

40%

Heat

PureCell® Model 400

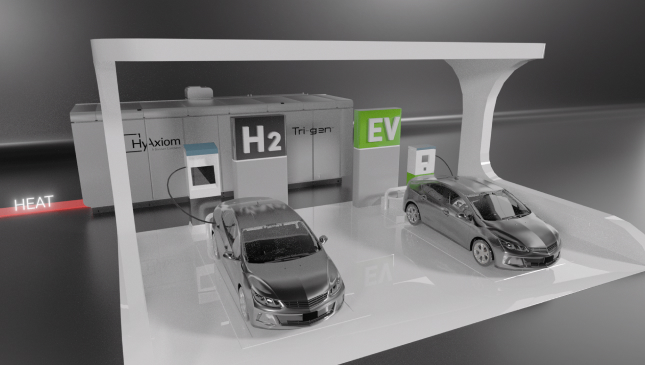

Tri-Gen System

This modification of the PureCell® Model 400 co-generates hydrogen, electricity and heat on-site simultaneously making it optimal for use in electric and hybrid vehicle charging stations.

Key Features & Benefits

- This modification of the PureCell® Model 400 co-generates hydrogen, electricity and heat on-site simultaneously making it optimal for use in electric and hybrid vehicle charging stations.

- Zero Emissions

- 24/7 Power and Heat

Ready to Get Started?

Contact our team to learn more about starting your project.

Our Upcoming Hydrogen Solutions

HyAxiom continues to be at the forefront of the hydrogen revolution delivering a full spectrum of reliable, cost-effective hydrogen solutions for a carbon-free future. You can look forward to these stationary fuel cell, maritime and mobility offerings in the very near future:

Solid Oxide Fuel Cell (SOFC)

Proton Exchange Membrane (PEM) Fuel Cell Powerpacks

Solid-Oxide Fuel Cell Propulsion System